Description

PRECISION NH3 APPLICATION IS POSSIBLE

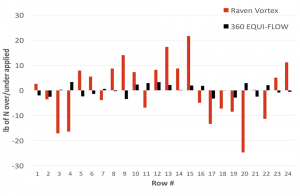

360 EQUI-FLOW keeps NH3 in a liquid state all the way down the knife. This ensures equal distribution from row to row. Testing conducted internally by the 360 Yield Center team revealed that cold flows systems have as much as 45 lbs of variance from knife to knife, with some rows as much as 22 lbs over target and some as much as 22 lbs under. 360 EQUI-FLOW showed only 8 lbs of variance, ranging from 4 lbs over target to 4 lbs under.

360 EQUI-FLOW uses a pressurized delivery system to keep anhydrous in the liquid form all the way to the knife because flow meters are accurate with liquid, but inaccurate with a mix of vapor and liquid. Rather than the 45 lbs of variation seen in tank-pressure systems, 360 EQUI-FLOW reduced variability to around 8 lbs.

HOW 360 EQUI-FLOW WORKS

Traditional anhydrous ammonia systems rely on tank pressure for distribution and injection. 360 EQUIFLOW takes a different approach:

Step 1: Ammonia from the tank is delivered to the initial filter.

Step 2: In the Liquimatic tower, the ammonia is separated into gas and liquid. The vapor is condensed back down into liquid and it all moves to the pump.

Step 3: The hydraulically driven centrifugal pump pushes 100% liquid ammonia through the flow meter and control valve to the manifold.

Step 4: The equal distribution manifold equalizes flow to each outlet.

Step 5: Every row gets the same amount of ammonia in liquid state.

VARIABLE ORIFICE MANIFOLD – AVAILABLE FOR FALL 2017

The Variable Orifice Manifold for 360 EQUI-FLOW allows operators to vary NH3 application rates to match the variability of soil types, slopes and organic matter. The system is controlled through the 360 Yield Center controller iPad app or through a John Deere display. Users can quickly and easily control both the 360 EQUI-FLOW system and the Variable Orifice Manifold.

The manifold maintains rate automatically by adjusting variable orifices without any user input, while pressure sensors on each row monitor for plugged or blocked rows and send data to the iPad app. A positive shutoff and flowmeter at each section manifold more accurately meters the flow rate through each section and eliminates the need for additional valves.

The Variable Orifice Manifold will be available for use in application this fall.